Top 10 Continuous Improvement Strategies That Actually Work

Discover continuous improvement strategies that actually boost performance and efficiency. Practical steps you can apply today to drive real results and growth.

Remember that one project that felt like pushing a boulder uphill in flip-flops? We've all been there. That nagging feeling that things could be smoother, faster, or just… less frustrating is a universal experience. That’s where the magic of continuous improvement comes in. It's not about massive, scary overhauls overnight. It’s about making smart, consistent tweaks that add up to huge wins over time.

Think of it as upgrading your business operations from dial-up to fiber optic, one intelligent step at a time. This isn't just for manufacturing floors or massive corporations; these principles apply whether you're a content creator, a software developer, or an entrepreneur. To truly 'make things better (for real)', mastering fundamental approaches like Master Continuous Integration strategies is crucial for modern development and delivering value efficiently.

In this guide, we're ditching the robotic jargon and diving deep into 10 powerful continuous improvement strategies you can actually use. We’ll explore how these frameworks can transform your workflow, boost your team's morale, and help you innovate faster. We'll even show you how an AI powerhouse like Zemith can act as your co-pilot, using its Document Assistant and Smart Notepad to supercharge these very strategies. Ready to stop tweaking and start transforming? Let's get started.

1. Lean Manufacturing

Lean manufacturing is less about being a penny-pincher and more about being a ruthless waste-eliminator. Originating from the legendary Toyota Production System, this strategy is laser-focused on maximizing customer value by systematically cutting out everything that doesn't add to it. Think of it as the Marie Kondo method for your business processes: if it doesn't spark joy (or value) for the customer, thank it and let it go. This approach streamlines workflows, shrinks lead times, and boosts overall efficiency.

This isn't just for car giants like Toyota. Nike optimized its supply chain using Lean, and even healthcare institutions have adopted it to slash patient wait times. For a deeper dive into optimizing output, consider actionable strategies, including lean principles, to how to improve manufacturing productivity.

How to Get Started with Lean

Getting lean doesn't mean you have to start doing corporate yoga (though it couldn't hurt). Here are some practical steps:

- Map Your Value Stream: Grab a whiteboard (or a collaborative document in Zemith) and chart out your entire process from start to finish. This is the best way to visually pinpoint where the "muda" (waste) is hiding.

- Embrace the 5S Methodology: This is a workplace organization method that stands for Sort, Set in Order, Shine, Standardize, and Sustain. It’s a simple but powerful way to create a more efficient and less chaotic workspace. More on this later!

- Run Kaizen Events: These are short-term, focused projects aimed at making rapid improvements. Get your frontline team involved; they often have the best insights into what’s really going on.

By focusing on these continuous improvement strategies, you can build a more agile and efficient operation. You can learn more about how to boost your team's workflow efficiency on zemith.com.

2. Six Sigma

If Lean Manufacturing is about eliminating waste, Six Sigma is its data-obsessed cousin, focused on eliminating defects. Popularized by Motorola and perfected at General Electric, this methodology uses statistical analysis to get processes as close to perfect as humanly (and statistically) possible. The goal is to reduce defects to a mind-bogglingly low rate: just 3.4 per million opportunities. It’s less about gut feelings and more about cold, hard data telling you exactly where the problems are. Think of it as the Sherlock Holmes of quality control.

This isn't just for manufacturing behemoths. Bank of America used Six Sigma to reduce errors in customer service, and 3M applied it to slash product defects, proving its power across various industries. The core idea is that if you can measure it, you can improve it. For businesses aiming to build an almost flawless reputation, these continuous improvement strategies are a game-changer. You can find more insights on applying data-driven approaches to improve team efficiency on zemith.com.

How to Get Started with Six Sigma

You don't need a PhD in statistics to start, but you do need a commitment to data-driven decisions. Here’s how to begin:

- Define, Measure, Analyze, Improve, Control (DMAIC): This five-phase framework is the heart of Six Sigma. It’s a structured, scientific approach to problem-solving that guides you from identifying the issue to implementing a lasting solution.

- Build Your Team: Assemble a team with defined roles (like Green Belts and Black Belts, if you want to get official). Proper training is key, as they’ll be the ones digging into the data and leading improvement projects.

- Focus on Customer-Critical Metrics: Don’t try to fix everything at once. Start by identifying the processes that have the biggest impact on your customers and your bottom line. Use data to pinpoint where the most significant variations and defects are occurring.

3. Kaizen (Continuous Improvement)

Kaizen is the powerhouse philosophy that proves small hinges can swing big doors. A Japanese term meaning "change for the better," it ditches the idea of massive, disruptive overhauls in favor of small, consistent, and incremental improvements. The magic of Kaizen is that it involves everyone, from the CEO to the frontline worker, creating a culture where a constant stream of tiny enhancements leads to monumental long-term results. It’s about making things a little bit better, every single day.

This is the very engine that powered Toyota's rise to dominance, with daily Kaizen activities happening across every single department. It’s not just for manufacturing; Canon used it to gain an edge in the camera market, and healthcare systems in Japan have drastically reduced hospital errors by empowering nurses to suggest small procedural tweaks. These continuous improvement strategies demonstrate that sustained, collective effort is often more powerful than a single revolutionary idea.

How to Get Started with Kaizen

Ready to make small changes with big impact? You don't need a massive budget, just a shift in mindset. Here are a few practical steps to bring Kaizen into your team's DNA:

- Hold Daily Team Huddles: Start each day with a quick, 15-minute standing meeting. Discuss what went well yesterday, what didn't, and one small thing the team can try to improve today.

- Establish a "Good Idea" System: Create a simple, accessible way for anyone to submit an improvement suggestion, no matter how small. A shared document in Zemith or a dedicated chat channel works perfectly. Make sure to review and reward all ideas, even the ones you don't implement, to encourage participation.

- Celebrate the Small Wins: When a small improvement works, make a big deal out of it! Publicly celebrating these tiny victories builds momentum and reinforces the value of the Kaizen culture.

By embedding these Kaizen principles, you turn your team into a proactive problem-solving machine. For more ideas on structuring these efforts, explore how to build a high-performance team on zemith.com.

4. Total Quality Management (TQM)

Total Quality Management (TQM) is the ultimate team sport for business. It’s a philosophy where every single person in the organization, from the CEO to the newest intern, is obsessed with delivering top-notch quality. Instead of having a "quality department" that swoops in to inspect things at the end, TQM weaves quality into the very fabric of every process. The goal is to prevent defects before they even happen, ensuring customer satisfaction is the North Star guiding every decision.

This isn't just a feel-good theory; it's a proven turnaround strategy. Xerox famously used TQM to fight off competitors in the 1980s, and Ford Motor Company dramatically improved vehicle reliability with these principles. Even hospitals apply TQM to enhance patient care and safety outcomes, proving its versatility. It's one of the most comprehensive continuous improvement strategies for enhancing customer loyalty because it treats quality as a shared, organization-wide responsibility.

How to Get Started with TQM

Ready to make quality everyone's job? You don't need to hand out magnifying glasses to every employee. Here are some practical first steps:

- Get Leadership On Board: TQM fails without unwavering commitment from the top. Leaders must champion the quality-first mindset and provide the resources to make it happen.

- Focus on the Customer: Actively gather and analyze customer feedback. Use surveys, reviews, and direct conversations to understand what "quality" truly means to them, then build your processes around that.

- Train, Train, and Retrain: Equip your teams with the tools and knowledge they need to improve their own work. This involves training in problem-solving, statistical process control, and understanding how their role impacts the final product or service. This process often involves strong information sharing, which you can learn about in these knowledge management strategies on zemith.com.

5. Agile Methodology

Agile isn't just for coders hunched over keyboards in Silicon Valley; it's a mindset focused on moving fast, adapting to change, and delivering value in small, digestible chunks. Born from the need to escape rigid, slow-moving project management, Agile breaks down big projects into short cycles called "sprints." This iterative process is all about flexibility, customer collaboration, and getting continuous feedback, allowing teams to pivot on a dime instead of steering a massive ship straight into an iceberg.

This approach has revolutionized how companies operate. Spotify famously uses an Agile squad model to innovate its platform, while tech giants like Google and Microsoft have embraced it to stay ahead of the curve. Even marketing teams use it to launch and adapt campaigns with lightning speed. The core idea is simple: stop planning everything to death and start doing, learning, and improving. What's one thing you could "sprint" on this week?

How to Get Started with Agile

Ready to ditch the waterfall and start sprinting? Here are a few practical steps to introduce these continuous improvement strategies to your workflow:

- Form Small, Cross-Functional Teams: Assemble a "squad" with all the skills needed to complete a project slice from start to finish. This breaks down silos and speeds up decision-making.

- Maintain a Prioritized Backlog: This is your team's master to-do list. Keep it organized and ranked by priority, so everyone knows what to tackle next without constant meetings. You can manage this easily in a tool like Zemith, keeping everyone on the same page.

- Run Regular Retrospectives: After each sprint, huddle up to discuss what went well, what didn't, and what to improve next time. This built-in feedback loop is the engine of Agile's continuous improvement.

6. Plan-Do-Check-Act (PDCA) Cycle

The Plan-Do-Check-Act (PDCA) cycle is the original scientific method for getting things done better. Popularized by W. Edwards Deming, this four-step model is a simple yet powerful framework for iterative improvement. It’s less about a giant, one-time overhaul and more about making small, calculated changes, learning from them, and then doing it all over again. Think of it as a feedback loop on steroids that keeps your processes evolving and getting sharper over time.

This isn't just for factory floors. Software teams use PDCA to crush recurring bugs, healthcare systems use it to reduce infections, and call centers apply it to boost customer satisfaction scores. For a closer look at how structured methods like PDCA can refine your operations, you can learn more about how to streamline business processes on zemith.com.

How to Get Started with PDCA

Putting the PDCA cycle into motion is like learning a new dance: plan your moves, try them out, see if you're stepping on any toes, and then adjust. Here’s how:

- Plan: Identify a problem or an opportunity for improvement. Don't just guess; use data to form a hypothesis about what changes will yield the best results. Get your team involved to brainstorm potential solutions.

- Do: Implement your plan on a small scale first. This is a pilot test, not a full-scale rollout. A limited test reduces risk and makes it easier to measure the impact of your changes without disrupting everything.

- Check: This is where you analyze the results of your pilot. Did your change have the desired effect? Compare the new data against your initial baseline to see what worked, what didn't, and what was completely unexpected.

- Act: Based on your findings, it's time to make a decision. If the change was successful, standardize it and implement it across the board. If it wasn't, take what you learned and start the cycle over again with a new plan. Lather, rinse, repeat!

7. Root Cause Analysis (RCA)

Root Cause Analysis (RCA) is less about playing the blame game and more about playing detective. Instead of just slapping a bandage on a problem, this strategy dives deep to find out why the problem happened in the first place. Think of it like a doctor who doesn't just give you cough syrup but runs tests to see if you have an underlying infection. RCA is a systematic approach to dig past the obvious symptoms and unearth the fundamental issue, ensuring it doesn't pop up again.

This problem-solving framework is a cornerstone in industries where mistakes are costly. The aviation industry uses it to investigate accidents, healthcare facilities analyze patient safety events, and IT teams deploy it to trace data breaches back to their origin. By focusing on the "why" behind the "what," these sectors build more resilient and safer systems, making it one of the most critical continuous improvement strategies for small businesses and large enterprises alike.

How to Get Started with RCA

Ready to put on your detective hat? You don't need a magnifying glass, but a curious mindset is non-negotiable. Here are some practical steps:

- Ask "Why" Like a Toddler: This is the core of the "5 Whys" technique. When a problem occurs, ask "why?" and then ask "why?" to that answer, and so on, typically five times. This simple but powerful method peels back the layers of a problem to reveal the core issue.

- Draw a Fishbone Diagram: Also known as an Ishikawa diagram, this visual tool helps you brainstorm and categorize all potential causes of a problem. It looks like a fish skeleton, organizing causes into categories like People, Process, and Technology to ensure you don't miss anything.

- Focus on Systems, Not People: The goal of RCA is to improve the process, not to point fingers. Creating a blame-free environment encourages honest participation and helps everyone focus on finding a real, lasting solution.

By digging deeper into problems, you can implement fixes that last. To explore more ways to tackle challenges head-on, you can discover a variety of creative problem-solving techniques on zemith.com.

8. Benchmarking

Benchmarking is the strategic equivalent of peeking at your neighbor's test paper, but without the risk of detention. It's a systematic process of measuring your company's products, services, and processes against those of industry leaders or top competitors. The goal isn't just to copy them, but to understand what makes them so good and adapt those winning strategies to your own context. It's about finding out "what's possible" and then figuring out how to get there.

This isn't a new-fangled idea. Xerox famously pioneered this in the late 1970s, comparing its own processes against its Japanese competitors to claw back market share. Today, airlines obsessively benchmark on-time performance, and call centers compare average handling times. It's one of the most powerful continuous improvement strategies for gaining a competitive edge because it provides a clear, data-driven roadmap for excellence.

How to Get Started with Benchmarking

Ready to see how you stack up? Here’s how to start this comparative analysis:

- Identify What to Benchmark: Don't try to measure everything. Pick a specific process that has a high impact on customer satisfaction or your bottom line, like inventory turnover or new customer onboarding.

- Find Your Benchmark Partners: Look for organizations that are nailing the process you want to improve. This could be a direct competitor or a leader in a completely different industry with a similar process.

- Collect and Analyze Data: This is the core of benchmarking. Gather quantitative data (metrics, costs) and qualitative data (how they actually do it). The "how" is often more valuable than the "what." This method provides solid information, which is a cornerstone of evidence-based decision making on zemith.com.

- Adapt, Don't Just Adopt: Once you have your insights, don't just copy-paste. Tailor the best practices to fit your company's unique culture, resources, and goals. Set realistic targets and start implementing the changes.

9. 5S Methodology

The 5S Methodology is the ultimate decluttering hack for your workspace, but instead of just sparking joy, it sparks efficiency and safety. Born from Japanese manufacturing, this system uses five principles to create a super-organized, high-performing environment. It's about more than just a spring clean; it's a philosophy for eliminating waste, reducing errors, and making problems immediately visible. Think of it as creating a workplace so organized that anyone can find anything in under 30 seconds.

This isn't just for factory floors. Operating rooms use 5S to improve surgical safety, and even software development teams apply it to organize digital assets. It’s one of those foundational continuous improvement strategies that lays the groundwork for more complex initiatives. By creating a visual and orderly workspace, teams can focus less on searching and more on creating value.

How to Get Started with 5S

Ready to bring some order to the chaos? Here’s how to implement the five pillars:

- Sort (Seiri): Go through everything in a workspace and remove what's unnecessary. If you haven't used that stapler from 2005, it's time to say goodbye.

- Set in Order (Seiton): A place for everything, and everything in its place. Arrange necessary items logically so they are easy to find, use, and return.

- Shine (Seiso): Clean the workspace thoroughly. This isn't just about hygiene; it’s a form of inspection that helps spot maintenance issues early.

- Standardize (Seiketsu): Create rules and procedures to keep the first three S's in check. Use visual cues like labels and outlines to make the standard obvious.

- Sustain (Shitsuke): This is the toughest part. Make 5S a habit through regular audits, training, and making it part of the daily routine.

10. Balanced Scorecard

The Balanced Scorecard is like your car's dashboard, but for your business. It stops you from fixating only on the speedometer (revenue) while ignoring your engine temperature or fuel level. Developed by Robert Kaplan and David Norton, this framework provides a holistic view of your organization by measuring performance across four key areas: financial, customer, internal processes, and learning and growth. It ensures your short-term actions are directly contributing to your long-term strategic goals.

This isn't just for Wall Street wizards. Fortune 500 companies use it for strategic management, but so do non-profits to balance their mission with financial health. For example, a bank might use it to manage risk, while a hospital uses it to improve patient outcomes. It’s one of those continuous improvement strategies that forces you to see the bigger picture, preventing you from winning a battle only to lose the war.

How to Get Started with the Balanced Scorecard

Ready to get a 360-degree view of your operations? Here are a few practical steps to build your own scorecard:

- Limit Your Objectives: Don't try to track everything. Stick to 4-7 strategic objectives for each of the four perspectives to maintain focus and avoid getting lost in the data.

- Cascade Downwards: Your top-level scorecard is great, but its real power is unlocked when it's cascaded down to departments and even individuals. This aligns everyone's daily work with the company's grand vision.

- Review Religiously: This isn't a "set it and forget it" tool. Schedule regular monthly or quarterly reviews with your leadership team to analyze performance, discuss what's working, and adjust what isn't.

By implementing the Balanced Scorecard, you can better align your team and resources. For more on achieving strategic alignment, explore how to improve team collaboration at zemith.com.

Top 10 Continuous Improvement Strategies Comparison

| Method | 🔄 Implementation Complexity | ⚡ Resource Requirements & Efficiency | 📊 Expected Outcomes | 💡 Ideal Use Cases | ⭐ Key Advantages |

|---|---|---|---|---|---|

| Lean Manufacturing | High — requires cultural change and training | Moderate–High resources; ⚡ improves lead time and throughput | Lower costs, faster cycles, improved quality | Repetitive manufacturing, supply-chain optimization | Waste elimination, scalable efficiency |

| Six Sigma | Very High — structured, statistical and governance-heavy | High (training, software, certified belts); efficient after maturity | Dramatic defect reduction, measurable cost savings | Quality-critical, high-volume production, finance | Data-driven defect elimination, clear ROI |

| Kaizen (Continuous Improvement) | Low–Medium — cultural adoption needed over time | Low resources per change; steady ⚡ productivity gains | Slow, cumulative improvements and higher engagement | Any organization seeking continuous cultural improvement | Employee empowerment, sustainable gains |

| Total Quality Management (TQM) | Very High — organization-wide cultural and process overhaul | High (training, systems, long-term investment); improves efficiency long-term | Improved customer satisfaction, systemic quality | Large organizations pursuing enterprise-wide quality | Holistic quality focus, supplier and customer alignment |

| Agile Methodology | Medium — team/process changes; scaling is complex | Low–Medium resources; ⚡ enables rapid delivery and feedback | Frequent value delivery, better market responsiveness | Software, product development, marketing teams | Flexibility, faster iterative value delivery |

| PDCA Cycle | Low — simple four-step iterative approach | Low resources; built for small-scale tests, may be slower for urgent issues | Reduced implementation failures, incremental validated gains | Process pilots, continuous improvement initiatives | Easy to learn, promotes evidence-based cycles |

| Root Cause Analysis (RCA) | Medium–High — requires skilled facilitation and thorough investigation | Medium resources; time-intensive but cost-effective vs repeated fixes | Fewer recurring problems, improved system reliability | Incident investigation in safety, healthcare, IT, manufacturing | Identifies permanent fixes, prevents recurrence |

| Benchmarking | Medium — requires comparative analysis and adaptation | Medium–High (data collection, external research); can accelerate improvements | Clear performance gaps, realistic targets, faster learning | Strategic planning, competitive analysis, performance improvement | Learns best practices, sets realistic goals |

| 5S Methodology | Low — straightforward, shop-floor focused | Low resources; ⚡ quick visible gains but needs sustainment | Improved workplace organization, safety, reduced search time | Workbenches, warehouses, ORs, offices starting Lean | Fast ROI, foundation for other improvements |

| Balanced Scorecard | High — strategic mapping, metric selection and governance | Medium–High resources; ongoing measurement and review | Aligned objectives, better strategic decision-making | Strategy execution in mid-large orgs, nonprofits, government | Translates strategy into measurable action across perspectives |

Your Turn: Go Forth and Improve!

Whew, that was a marathon, not a sprint! We've journeyed through ten powerful continuous improvement strategies, from the structured discipline of Six Sigma to the collaborative spirit of Agile. Each one offers a unique lens through which to view your work, whether you're a developer squashing bugs, a marketer optimizing a campaign, or an entrepreneur building a business from scratch.

It's easy to look at a list like this and feel a sudden urge to implement everything at once. Resist that urge! The secret to successful continuous improvement isn't about a massive, disruptive overhaul. It's about a consistent, gentle pressure applied over time. Think of it less like a tidal wave and more like a river carving a canyon; the change happens through persistent, focused action.

The Real Takeaway: Start Small, Think Big

The most crucial takeaway from this entire guide is simple: pick one thing.

Don't try to roll out a full Kaizen philosophy, a Six Sigma green belt program, and a Balanced Scorecard all in the same quarter. That’s a recipe for burnout, not a breakthrough. Instead, look back at the strategies we covered:

- Did the 5S Methodology make you glance nervously at your cluttered desktop and chaotic file folders? Start there.

- Are you constantly fixing the same recurring problem? It might be time for a simple Root Cause Analysis using the "5 Whys."

- Does your team feel disconnected from the company's high-level goals? Perhaps a simplified Balanced Scorecard could bridge that gap.

The goal isn't to become a master of all ten methodologies overnight. The goal is to solve a real problem you're facing right now. By choosing one of these continuous improvement strategies and applying it to a specific, tangible issue, you create a small win. That small win builds momentum, proves the value of the process, and makes it easier to tackle the next improvement.

Your First Step on the Improvement Journey

The journey of a thousand miles begins with a single step, and your journey toward a more efficient, effective, and less frustrating workflow is no different. The ultimate value of mastering these concepts is empowerment. It’s about trading a reactive "firefighting" mode for a proactive "fire-prevention" mindset. It's about giving yourself and your team the tools to not just do the work, but to make the work itself better.

So, what's your first step? Is it running a PDCA cycle on your morning routine? Using benchmarking to see how your content strategy stacks up? Or maybe just sorting your project files so you can finally find that one document from last May? Whatever it is, commit to it. Document your starting point, track your progress, and celebrate the improvement, no matter how small. That's the heart of continuous improvement in action.

Ready to put these strategies into practice without the chaos of a dozen different tools? Zemith is your all-in-one AI workspace designed to centralize your research, brainstorming, and documentation. Streamline your continuous improvement efforts by trying Zemith today and turn your great ideas into even better results.

Explore Zemith Features

Introducing Zemith

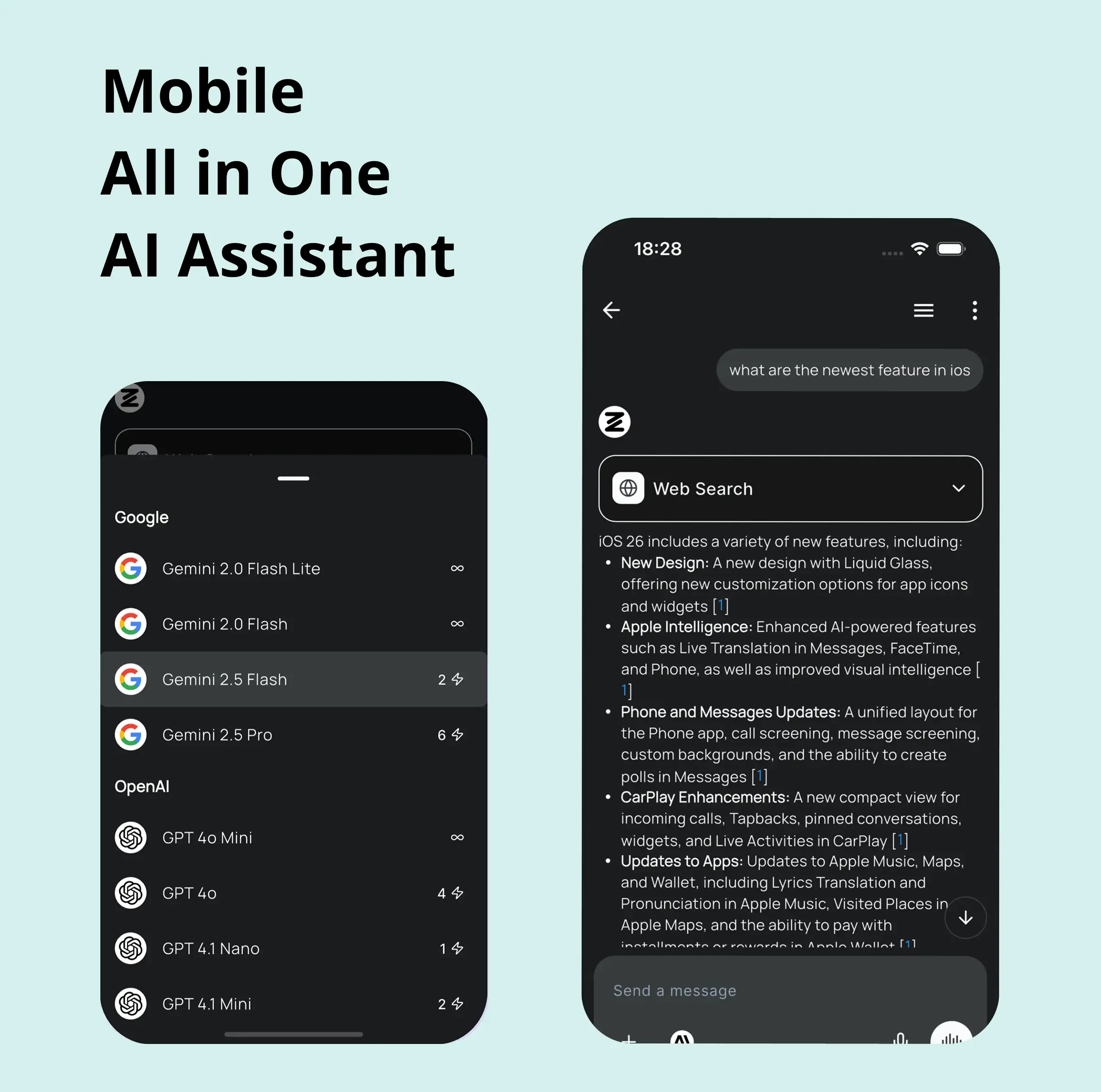

The best tools in one place, so you can quickly leverage the best tools for your needs.

All in One AI Platform

Go beyond AI Chat, with Search, Notes, Image Generation, and more.

Cost Savings

Access latest AI models and tools at a fraction of the cost.

Get Sh*t Done

Speed up your work with productivity, work and creative assistants.

Constant Updates

Receive constant updates with new features and improvements to enhance your experience.

Features

Selection of Leading AI Models

Access multiple advanced AI models in one place - featuring Gemini-2.5 Pro, Claude 4.5 Sonnet, GPT 5, and more to tackle any tasks

Speed run your documents

Upload documents to your Zemith library and transform them with AI-powered chat, podcast generation, summaries, and more

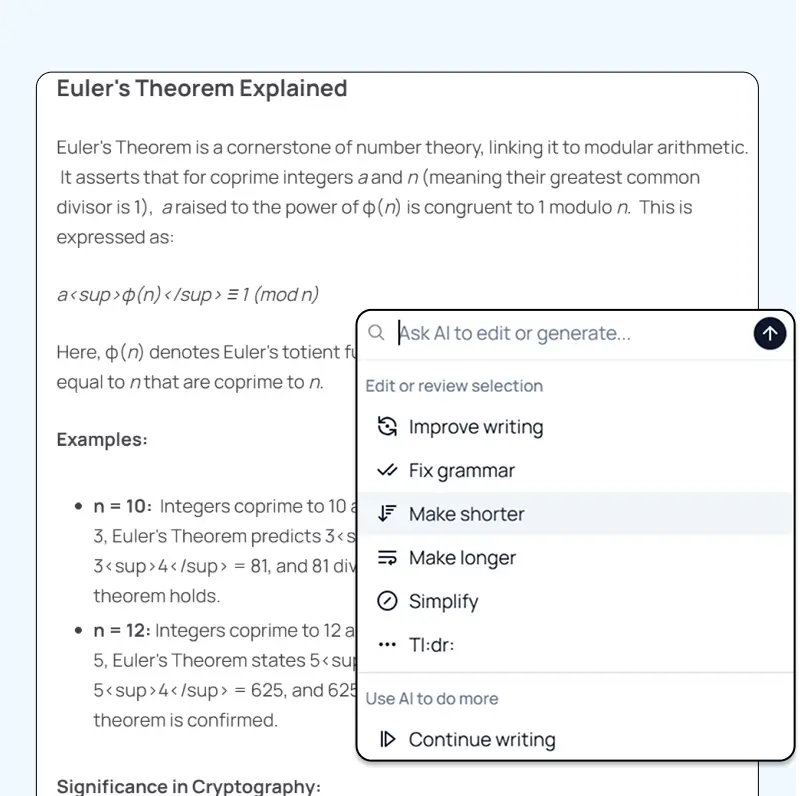

Transform Your Writing Process

Elevate your notes and documents with AI-powered assistance that helps you write faster, better, and with less effort

Unleash Your Visual Creativity

Transform ideas into stunning visuals with powerful AI image generation and editing tools that bring your creative vision to life

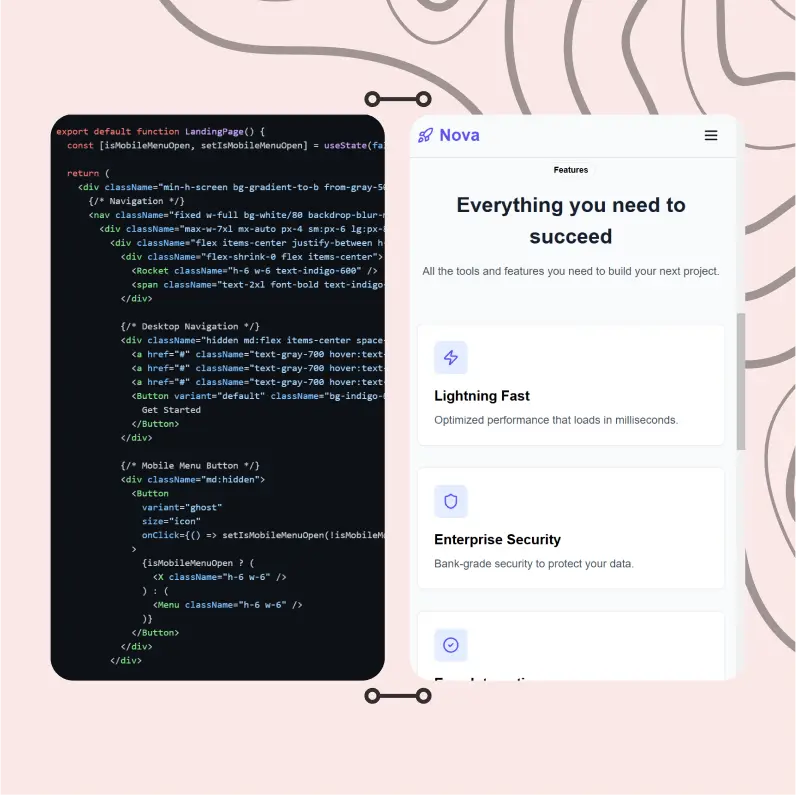

Accelerate Your Development Workflow

Boost productivity with an AI coding companion that helps you write, debug, and optimize code across multiple programming languages

Powerful Tools for Everyday Excellence

Streamline your workflow with our collection of specialized AI tools designed to solve common challenges and boost your productivity

Live Mode for Real Time Conversations

Speak naturally, share your screen and chat in realtime with AI

AI in your pocket

Experience the full power of Zemith AI platform wherever you go. Chat with AI, generate content, and boost your productivity from your mobile device.

Deeply Integrated with Top AI Models

Beyond basic AI chat - deeply integrated tools and productivity-focused OS for maximum efficiency

Straightforward, affordable pricing

Save hours of work and research

Affordable plan for power users

Plus

- 10000 Credits Monthly

- Access to plus features

- Access to Plus Models

- Access to tools such as web search, canvas usage, deep research tool

- Access to Creative Features

- Access to Documents Library Features

- Upload up to 50 sources per library folder

- Access to Custom System Prompt

- Access to FocusOS up to 15 tabs

- Unlimited model usage for Gemini 2.5 Flash Lite

- Set Default Model

- Access to Max Mode

- Access to Document to Podcast

- Access to Document to Quiz Generator

- Access to on demand credits

- Access to latest features

Professional

- Everything in Plus, and:

- 21000 Credits Monthly

- Access to Pro Models

- Access to Pro Features

- Access to Video Generation

- Unlimited model usage for GPT 5 Mini

- Access to code interpreter agent

- Access to auto tools

- 10000 Credits Monthly

- Access to plus features

- Access to Plus Models

- Access to tools such as web search, canvas usage, deep research tool

- Access to Creative Features

- Access to Documents Library Features

- Upload up to 50 sources per library folder

- Access to Custom System Prompt

- Access to FocusOS up to 15 tabs

- Unlimited model usage for Gemini 2.5 Flash Lite

- Set Default Model

- Access to Max Mode

- Access to Document to Podcast

- Access to Document to Quiz Generator

- Access to on demand credits

- Access to latest features

- Everything in Plus, and:

- 21000 Credits Monthly

- Access to Pro Models

- Access to Pro Features

- Access to Video Generation

- Unlimited model usage for GPT 5 Mini

- Access to code interpreter agent

- Access to auto tools

What Our Users Say

Great Tool after 2 months usage

simplyzubair

I love the way multiple tools they integrated in one platform. So far it is going in right dorection adding more tools.

Best in Kind!

barefootmedicine

This is another game-change. have used software that kind of offers similar features, but the quality of the data I'm getting back and the sheer speed of the responses is outstanding. I use this app ...

simply awesome

MarianZ

I just tried it - didnt wanna stay with it, because there is so much like that out there. But it convinced me, because: - the discord-channel is very response and fast - the number of models are quite...

A Surprisingly Comprehensive and Engaging Experience

bruno.battocletti

Zemith is not just another app; it's a surprisingly comprehensive platform that feels like a toolbox filled with unexpected delights. From the moment you launch it, you're greeted with a clean and int...

Great for Document Analysis

yerch82

Just works. Simple to use and great for working with documents and make summaries. Money well spend in my opinion.

Great AI site with lots of features and accessible llm's

sumore

what I find most useful in this site is the organization of the features. it's better that all the other site I have so far and even better than chatgpt themselves.

Excellent Tool

AlphaLeaf

Zemith claims to be an all-in-one platform, and after using it, I can confirm that it lives up to that claim. It not only has all the necessary functions, but the UI is also well-designed and very eas...

A well-rounded platform with solid LLMs, extra functionality

SlothMachine

Hey team Zemith! First off: I don't often write these reviews. I should do better, especially with tools that really put their heart and soul into their platform.

This is the best tool I've ever used. Updates are made almost daily, and the feedback process is very fast.

reu0691

This is the best AI tool I've used so far. Updates are made almost daily, and the feedback process is incredibly fast. Just looking at the changelogs, you can see how consistently the developers have ...